Despite increasing levels of digital and large format printing in the UK, the offset lithographic process remains the most prolific print process and comes essentially in two forms, sheet fed (i.e. singular, pre-cut sheets of paper) or web (i.e. big reels of paper) offset.

You will no doubt have seen clips on TV of printing presses in action, or you may even have been round a printing company, but do you know how the process works?

Below we explain the offset litho print process and how it works.

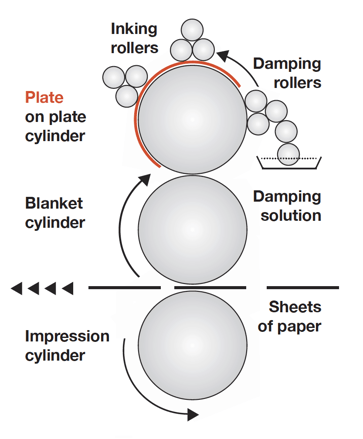

The process works as follows. Once a printing plate has been produced it is clamped round the plate cylinder inside the press. This is flanked by another cylinder called the ‘blanket cylinder’ and by a number of smaller rollers called inking and damping rollers.

Working on the premise that ink and water do not mix, the plate cylinder rotates inside the press and the inking and damping rollers distribute ink and water over the plate. The water acts as a carrier for the ink as it rests in suspension in the water.

The plate on the plate cylinder has right reading imaged and non imaged areas on it, depending on what is to be printed.

These imaged and non imaged areas either repel or attract the suspended ink, with the imaged areas attracting the ink.

Once the ink is on the plate, the plate cylinder continues to rotate and ‘offsets’ the inked image onto the rubber blanket cylinder, to form a mirrored or wrong reading image.

In the meantime a sheet of paper from the press’ paper feeder has been picked up and transported through the machine to the impression cylinder, where it is passed around it and is pushed hard up against the rubber blanket cylinder, which in turn offsets the image onto the sheet of paper.

This will print one colour onto the paper. To create a full colour images, or four colour process, four of these 'units' are placed sequentially one after another in a series. The paper passes through one unit to the next, building layers of cyan, magenta, yellow and black along the way. These are the four primary colours used in printing and are abbreviated to CMYK. You can find out more about CMYK and RGB and the difference between the two in this article.

If you would like to understand more, have any questions or would like to discuss a requirement, please contact our team or have a look at our print production capabilities to see how we might help you.

Next Story

1 Osier Way

Swan Business Park

Buckingham

MK18 1TB

01280 824000

info@bcqsolutions.com

Sign up for our latest insights, articles and news.

Your marketing. Transformed.